Services

A&H Services comes to you in the hangar or at your place of work. Everything you need to know about our work equipment, from the intended use, legal aspects, application examples to misuse, from sample images of new, used, misused equipment or repair instructions - you will find that in the application and maintenance instructions (AWA), parts 0 to 4.

Krzystof Lukaszewski (LMO) is responsible for the service division.

2006/42/EC relevant

When we talk about the maintenance, overhaul or repair of load lifting devices and slinging equipment, the regulations mean work equipment.

R (EU) 2016/425 relevant

We know every customer by their first name. Simple PCDS can be fully traced using an individual part number and serial number. This makes it easier to monitor rescue, work or intervention equipment.

Part 21 relevant

The ICA with AWA is decisive for your HEC equipment. "Chinese"? EASA! Instuction for continued airworthiness as well as application and maintenance instructions.

ANNEX I relevant

What applies everywhere and for everything applies here: we are your first point of contact for maintenance, overhaul or repair.

Control – inspection – advice – replacement – maintenance – repair – overhaul

The complete service - for your safety

As the user, you are responsible for its intended use and maintenance. We can support you in both cases. In our AWA parts 1 - 4 you will find (almost) everything that has accumulated in 40 years of experience.

Send us your work equipment and you will receive a professional inspection service:

- Visual assessment of all parts and materials

- Magnetic crack detection of steel parts (fluxing)

- Measure, function and conformity test (standards and rules conformity, security)

- Professional repairs within the framework of what is permissible and possible

- Completion of missing or replacement of defective labels and signs, rigging and protective coats

- Replacement of worn or defective parts (fittings, spare parts)

- Root cause analysis

Their benefits:

Safety

Safety is not a condition, but the result of proper procurement, handling, testing and maintenance.

Exact documentation

We attest the test carried out with test certificates and test badges.

Conformity

You can prove that you have fulfilled your legal responsibility at any time.

Repair Lines

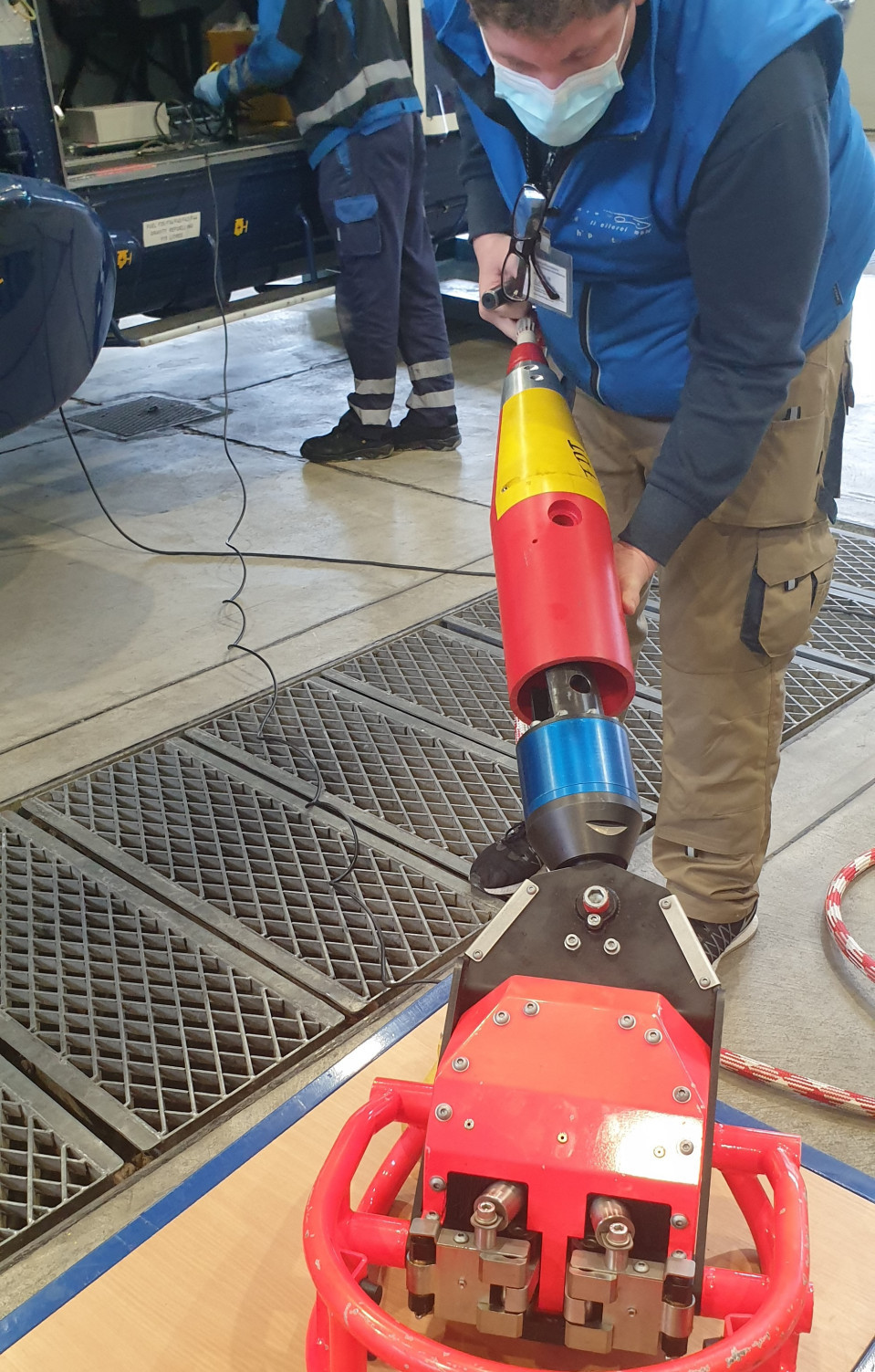

"Oops, that's it," some might think. A TLL transport line with a 50 kN WLL is a throwaway. Not so at AirWork & Heliseilerei GmbH (A&H). As the OEM of this unique helicopter transport longline, we are able to analyze and assess the damage and implement corrective measures.

Everything works together here: the design of the load-bearing core, the electrical conductor, the end clamp, and the protective sheath.

After four hours of work, the line is ready for use again.

Impressionen

Checklist for defining the desired service work by a customer

The testing service from A&H Services has been highly valued by our customers for many years. See where things are going next year and benefit when we are near you.

2025 Tour Germany

Inspection Tour Germany

Successfully completed for 2025. We'll meet again in 2026

Your contact: Krzysztof Lukaszewski +41 79 604 47 71

Inspection Tour REGA (Schweiz)

Start 2025: 09.06.2025

- 1. Stage: 09.06. - 11.06.2025

- 2. Stage: 16.06. - 18.06.2025

- 3. Stage: 07.07. - 10.07.2025

Your contact: Krzysztof Lukaszewski +41 79 604 478 71

Inspection Tour France

Successfully completed for 2025. We'll meet again in 2026

Your contact: Krzysztof Lukaszewski +41 79 604 47 71